Offshore wind leaders expand land, sea hubs to future-proof operations

Offshore wind operators are supplementing giant UK port-side investments with remote vessel expansions to optimize growing project capacities and portfolios, leading operators told New Energy Update.

Related Articles

In the coming months, Denmark's Orsted is expected to complete the construction of the U.K.'s largest offshore wind operations and maintenance (O&M) hub at Grimsby Royal Dock in north-east England.

Orsted’s East Coast Hub will initially support the company’s 210 MW Westermost Rough, 573 MW Race Bank and 1.2 GW Hornsea 1 wind farms. By the time the 1.4 GW Hornsea 2 project is completed in 2022, Orsted will employ some 400 staff at the East Coast Hub for decades to come. The company has pledged to spend some 6 billion pounds ($7.7 billion) in the wider Humber area by 2019.

The size of the project shows how leading offshore operators are scaling up operations to optimize growing project portfolios. Larger, higher efficiency turbines and improved installation practices have sliced capital expenditure costs, raising the importance of operational expenditure (opex).

Last month, Swedish group Vattenfall signed an agreement with infrastructure group Peel ports to reserve an area of Great Yarmouth Harbour in eastern England for a new offshore wind operations base.

The base will serve Vattenfall’s planned 1.8 GW Norfolk Vanguard and 1.8 GW Norfolk Boreas projects, set for government approval in 2019 and 2020. The hub is expected to host up to 150 skilled wind technicians for at least 25 years.

Installed offshore capacity by country (to 2017)

(Click image to enlarge)

Source: WindEurope, February 2018.

The buildout of UK onshore operations activities will provide a range of cost benefits for operators and is clearly a significant boost for local and regional industry.

At the same time, operators are expanding remote offshore capabilities to increase returns as larger projects are developed further from the shore, leading experts told New Energy Update.

Hub benefits

In February 2018, Orsted contracted local construction group Hobson & Porter to expand its existing O&M support facilities at Grimsby Royal Dock, including a warehouse expansion and new office buildings.

The operations hub will act as a base for vessel operations, including newly-built Service Operational Vessels (SOVs), and includes a marine and helicopter coordination center to provide 24/7 service operations.

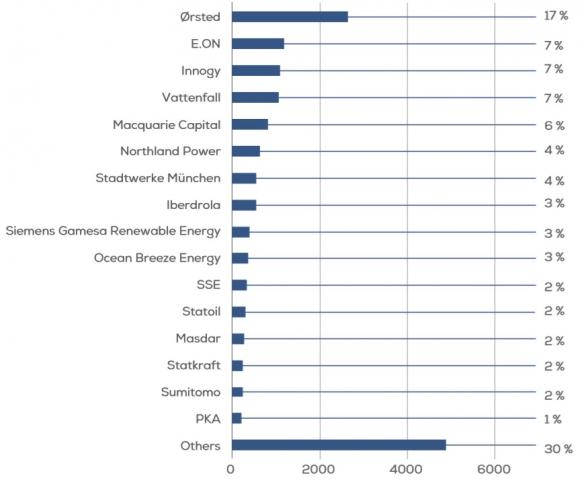

Owners share of installed offshore wind capacity (to 2017)

Source: WindEurope, February 2018.

Key benefits of large onshore operations hubs include the sharing between projects of onshore infrastructure, labor resources and spare parts warehouses, Fernando Sevilla Montoya, Senior Engineer, Renewables Projects Offshore, N&B at DNV GL, told New Energy Update.

The pooling of resources at centralized facilities can accelerate the sourcing of vessels and strategic components and support optimized framework agreements with vessel operators, Montoya said.

“Together with better communication and sharing of lessons learnt between projects, this could entail significant reductions in costs and resources required,” he said.

Shared spare parts storage facilities provide greater benefits for critical components which fail rarely, Robin Redfern, a partner at Everoze consultancy, said.

Co-locating onshore operations can also encourage information sharing and cross-project learning, Redfern noted.

Offshore outposts

Offshore operators are also expanding satellite operations hubs at sea to support larger projects further offshore. Companies like Orsted and Vattenfall are increasingly turning to specially-designed SOVs which can house skilled technicians for weeks and improve maintenance efficiency.

“As wind farms get further and further out to sea, it becomes more efficient for technicians to stay offshore for weeks at a time, rather than returning to shore every day,” an Orsted spokesperson said.

Orsted operates the 81m-long Edda Passat SOV out of its East Coast Hub to service its Race Bank project. Supplied by Norwegian shipping company Ostensjo Rederi and designed by Britain’s Rolls-Royce, the vessel spends up to 28 consecutive days out at sea, servicing six to eight turbines each day. The vessel holds 60 cabins and technicians work a two-week on, two-week off shift pattern and can transfer straight from the vessel onto a turbine.

Orsted will use a similar vessel, the Edda Mistral, to build and service Hornsea 1.

“In the construction phase, the Mistral will primarily be used by JDR Cables to complete the last step of the array cable termination, connecting the array cables to the turbine switchgear located in the transition piece,” an Orsted spokesperson said.

Remote control

Vattenfall plans to base crews onshore for wind farms situated up to 35 nautical miles from the shore, and base staff onboard SOVs for projects further out to sea, Hernan Vargas, Vattenfall’s UK lead on offshore O&M roadmap/ system design, told New Energy Update.

While both scenarios require efficient onshore coordination and component warehousing, some strategic or critical spares will be held onboard SOVs, Vargas said.

“This enables us to reduce the large [cost] footprint required for warehousing," he said.

Projects further offshore also require more spares and personnel as they tend to be much larger, Vargas noted.

For its Norfolk Vanguard and Norfolk Boreas projects, located 47 km and 72 km from the shore, Vattenfall plans to use a combination of SOVs and CTVs, with helicopter support for troubleshooting activities, he said.

Vattenfall will be able to apply the latest O&M learnings from its new 93 MW European Offshore Wind Deployment Centre (EOWDC) in north-east Scotland.

The construction of 11 large-scale turbines at the center provided installation learnings and going forward the center will test the latest O&M innovations.

By Neil Ford