As US cuts tariffs, bifacial builders test design gains

U.S. import tariff exemptions will spur activity in the fast-growing bifacial solar market and developers are implementing new tracker and structure designs in the first wave of projects.

Related Articles

The U.S. federal authorities' decision last week to exempt bifacial solar panels from Section 201 import tariffs will accelerate growth in the emerging bifacial market.

Demand for bifacial panels was already soaring and a first wave of projects this year is set to demonstrate the latest structure and layout learnings.

Leading tracker supplier NEXTracker is reportedly involved in over 750 MW of new bifacial solar projects in the U.S., including Invenergy's trailblazing 160 MW Southern Oak project, due online in Georgia this year. In April, Enel Green Power installed its first bifacial solar panels at the 220 MW Magdalena II solar plant in Tlaxcala, Mexico. Bifacial modules form part of a giant 1.8 GW module agreement between EDF Renewables North America and Canadian Solar.

Bifacial developers are favoring single-axis trackers that boost output, separate panels and minimize shading losses.

Bifacial plants can increase output by around 5 to 6% at relatively little extra cost, making them cost-competitive in the U.S., Chris Deline, PV engineer at NREL told New Energy Update.

Even before the tax exemption, bifacial projects offered a higher internal rate of return (IRR) in all U.S. regions, according to modelling by developer EDP Renewables (EDPR).

The modelling also showed multiple factors significantly impact bifacial plant performance.

Module height, shading and ground reflectance, can all affect productivity. Shading and mismatch factors can create output losses of 10 to 15% on a single axis tracker project, according to NREL.

Developers and suppliers are now working together to optimize the structures for bifacial plants and new technologies in the coming years are set to further improve performance.

New heights

Bifacial systems are forecast to represent 10% of the utility-scale market in 2019, rising to 30% by 2025, according to the National Renewable Energy Laboratory (NREL). By 2028, bifacial cells could represent 40% of the solar market, the International Technology Roadmap for Photovoltaic (ITRP), said.

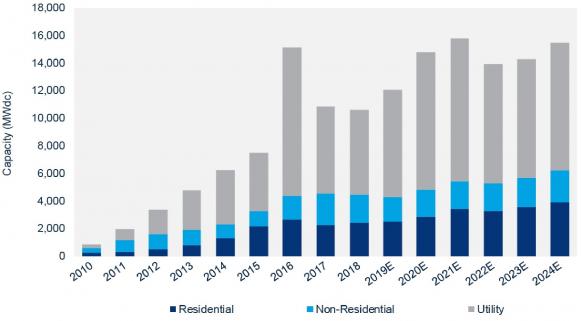

US PV installation forecast by segment

(Click image to enlarge)

Source: Wood Mackenzie Power and Renewables, March 2019.

Bifacial developers are modelling a greater number of irradiance metrics to improve plant performance.

EDPR used modelling to analyze the performance of different bifacial plant designs. A major global wind developer, EDPR aims to build up to 2 GW of solar power in 2019-2022.

Modelling showed module height can significantly impact bifacial plant performance, Itai Suez, Senior Solar Project Engineering Manager at developer EDP Renewables (EDPR), told the PV Operations Dallas 2019 conference in April.

Increasing the tracker height for a single portrait system from 1.5 meters to around 2.5 m could increase annual output by as much as 0.75%, Suez said.

Some landowners may opt to install bifacial panels at a height which allows them to simultaneously use the land for other purposes such as agriculture, Josh Stein, PV system analyst at Sandia National Laboratories, told New Energy Update.

"You can grow plants in between the rows. Also parking lots are another application, as you can drive between the rows,” he said.

Critical spacing

Developers must also optimize spacing in order to maximize rear-side exposure.

In one example, NEXTracker has adapted its mounting rails for bifacial plants, increasing distances between PV panels and the round torque tubes to minimize rear-side shadowing.

For its first commercial bifacial projects, Renewable Energy Systems (RES) has maintained standard foundation heights and focused on reducing system DC size and increasing row spacing, Beth Copanas, Solar engineering manager at RES, said.

RES is the EPC provider for the Southern Oak project and is developing other utility-scale bifacial plants.

To minimize shading on the rear side of bifacial modules, RES has selected adapted single axis tracking systems that increase the height of the backside of the module relative to the tracking system structure (module to torque tube), Copanas said.

"In addition, the DC wiring system is designed and installed to minimize shading of the rear side of the modules," she said.

For projects under development, RES is evaluating how to cost effectively replicate the gains made by test laboratories, manufacturers and smaller PV projects, Copanas said.

Another option is to use fixed-tilt panels positioned vertically, facing east-west, Stein said. These benefit from peak production in the morning and the afternoon, when electricity prices are higher.

“So there’s a benefit in both output and return,” he said.

Better bounce

To remain competitive, bifacial developers will need to find innovative ways to maximize ground reflectance.

Different ground conditions such as grass, dirt, wet dirt, dry sand and snow have vastly different reflective properties and developers may look to layer the ground with local materials to maximize reflectance, Suez told the conference in April.

"The economics of increasing your albedo fraction [ground reflectance] from 0.2 to 0.6 could be almost double your performance gain...this effect is pretty dramatic," he said.

Materials such as crushed shells are reportedly being used to boost reflectance.

Developers can use white rock to increase reflectance but this is relatively expensive, Stein said.

Bioengineering projects tackling greenhouse gas effects and climate change could help create solutions.

“In the future, there might be some sort of genetically-modified plant or grass, which reflects light that PV cells absorb," Stein said.

"Or some white powder that can be sprayed on the grass."

By Beatrice Bedeschi