Self-aligning heliostats arrive to slice CSP costs

Soon to hit the market, auto-calibrating heliostat systems will cut capex, accelerate construction times and expand siting potential, suppliers told New Energy Update.

Related Articles

As CSP developers drive for lower costs, heliostat performance has become a key area of research.

Heliostats can represent half of the capital costs of a CSP plant and misalignment can severely impact performance. Alignment issues become more significant for larger projects due to the greater distances between heliostat and CSP tower.

At NRG Energy’s giant 377 MW Ivanpah tower plant in California, online since 2014, heliostat positioning problems caused by soiling and windstorms contributed to the facility missing production targets in its first 24 months of operations. In 2016, misaligned heliostats caused a fire in a section of one of the plant’s towers, reducing output by a third for over a month.

A number of technology teams are now using the latest camera and automation tools to develop self-calibrating heliostat systems.

These solutions are set to have multiple benefits, accelerating construction times and improving plant performance, and could be deployed within a year, developers told New Energy Update.

Lower capex

PHOTON, a 2 million-euro ($2.2 million) project in Europe led by Spain’s Tewer Ingenieria, has integrated self-calibration into a new heliostat design.

Tewer and partners ACCIONA Industrial, Aalborg CSP, the Applied Research Institute F and Modern E-Technologies have developed a heliostat composite incorporating a spherically-curved sandwich of glass-foam-glass that reduces blocking issues and temperature-induced misalignment.

The system achieves an enhanced optical quality of 0.6 milliradian (mrad) deviation, compared with 2 mrad deviation for existing state-of-the-art heliostat models. The partners have integrated the technology with an autonomous wireless communication system, powered by PV, to provide self-calibration.

The heliostat learns its applicable kinematics by following the sun with a sensor built into the facet plane, Jose M. Blazquez Serrano, Project Engineer at Tewer, said.

The system removes the need for foundations, trenches and wiring in the heliostat field, reducing costs, he said.

Based on modelling at ACWA Power's planned 100 MW Redstone tower project in South Africa, the system can reduce capex by 29.7% and cut opex by 8.8%, reducing the overall levelized cost of energy by 11.9%, Blazquez said.

"We estimate that by Q4 this year we will have accumulated sufficient operating hours to demonstrate the solution," he said.

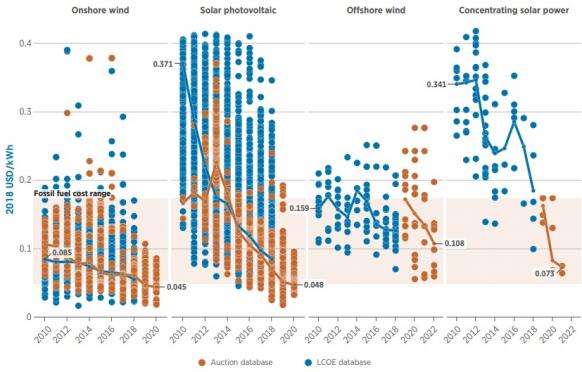

Global levelized costs for solar, wind in 2010-2022

(Click image to enlarge)

Source: IRENA's 'Renewable power generation costs in 2018' report (May 2019).

Factory savings

Auto-alignment solutions can allow developers to purchase lower-cost heliostats, manufactured through less precise methods than current models.

This could generate significant savings. Ivanpah, the world's largest CSP tower plant, uses 173,500 heliostats while the 100 MW tower under construction at the Noor Energy 1 project in Dubai includes 70,000.

Spanish groups CENER and IK4-TEKNIKER have developed a scalable heliostat calibration system (SHORT), which identifies cracking misalignments and recalibrates in "less than an hour,” Cristobal Villasante, Head of Thermal Engineering at IK4-TEKNIKER told New Energy Update.

A camera is attached to a low-cost heliostat and oriented to several targets placed in known positions, enabling the camera to compare actual and expected position. This process is repeated for several positions to produce the data to allow the heliostat to modify the tracking commands. The procedure can be automated so that no human interaction is required.

Tests have confirmed accuracies "better than 0.25 mrad,” and the final cost including required hardware would be "less than current offerings," Villasante said.

The system has already been demonstrated within several heliostats and the partners are looking to work with suppliers to develop a more "industrialized" and integrated solution, he said.

Advanced algorithms

U.S. CSP start-up Heliogen has created a cutting-edge computing solution that pushes performance boundaries, even with low-cost heliostat systems.

Backed by Bill Gates, Heliogen has developed an autonomous system that calibrates heliostats based on a "closed-loop" algorithm.

The system uses cameras and advanced computer vision software to align heliostats more accurately and increase solar efficiency. Tests have shown increased accuracy of reflected sunlight can achieve temperatures exceeding 1,000° C, the company said.

“We can achieve high pointing accuracy (sub-milliradian normal vector errors) with a comparatively low-cost drive system, because the closed-loop controller can correct for nonlinearities and other manufacturing variability that an open-loop controller would find difficult or impossible to correct,” Fatimah Bello, VP, Business Development & Product at Heliogen, said.

Faster construction

Smart calibration technology can rapidly reduce installation times and construction costs by allowing simultaneous calibration of heliostats.

“Our system eliminates the long process of calibration for the heliostat field – it’s a matter of hours to days to get the field up and running, not months,” Bello said.

Self-calibration solutions also allow for faster, low-cost planting methods for heliostats, further reducing labor costs. The installation benefits would be greatest at sites with large civil works requirements and high labor prices.

“One of the key benefits pursued with this technology is...to speed up and drive down costs during the start-up and commissioning of the solar field,” Blazquez said.

Market deployment

All of the developers see opportunities for retrofitting their self-calibrating heliostat technology to existing plants, although the cost-benefits would differ between the solutions and depend on site-specific factors.

Heliogen sees immediate opportunities for new plants that supply heat to industrial facilities with restricted land availability. By increasing the accuracy of the heliostats, smaller heliostat fields can be proposed at lower cost, Bello said.

“Just recently we were able to propose a heliostat field that was almost 20% smaller than the customer expected,” she said.

Heliogen is currently examining projects with payback periods of as low as two years, Bello said.

"We are currently proposing projects for Q4 2020 and Q1 2021 implementation," she said.

Reporting by Kerry Chamberlain

Editing by Robin Sayles