GE targets untapped wind sites with two-piece blade design

GE's new 5.3 MW turbine system combines larger dimensions with on-site blade assembly in a design leap that could unlock new wind siting opportunities.

Related Articles

Last month, GE unveiled a new 5.3 MW onshore wind turbine which is more than double the average capacity of turbines installed in the U.S. in 2017.

Larger, higher efficiency turbines and growing installation experience have dramatically reduced wind power costs. Taller turbines can access higher wind streams and design innovations have improved energy conversion.

Set for commercial launch in 2019, GE's new 5.3 MW design increases annual energy production (AEP) by up to 50% compared with GE's 3 MW turbines, according to the company. AEP is 4% higher than a prototype 4.8 MW model, currently under construction in Germany.

The latest model incorporates 77 meter blades. Longer blade lengths typically raise transport costs, but GE’s new system uses a two-piece carbon blade design, enabling the blades to be assembled on site.

GE’s segmented blade design will open up new wind development opportunities, Peter Wells, CEO of GE's Onshore Europe and Sub-Saharan Africa business, told New Energy Update.

“The two-piece blade design is intended to make it possible to more easily transport blades to land-constrained locations that are relatively difficult to access with larger blades,” Wells said.

Improved access for larger turbines should make more sites become "economically viable" but segmented blades will incur specific costs, Ian Baring-Gould, Research & Deployment Program Manager at NREL’s National Wind Technology Center, said.

The two-piece blades will require additional “hard points” for joining, incurring manufacturing and maintenance costs, while the larger overall dimensions will increase component weight, Baring-Gould said.

Turbine sizes are growing at a rapid rate and “the jury is still out” on the overall benefits of the latest models, he said.

GE will need to implement significant manufacturing, installation and maintenance efficiencies to minimize the total costs of these larger units.

Site flexibility

GE's new design is based on its Cyprus platform which is "designed to scale over time, enabling GE to offer a wider array of power ratings and hub heights to meet customer needs throughout the 5 MW range," according to the company.

Hub heights are available at 101 m and 120.9 m with a tubular tower; and 150 m and 161 m with a hybrid concrete tower. Blade tips can be customized based on factors such as wind speed and local climate.

A large number of U.S. wind projects are continuing to employ multiple turbine configurations from a single supplier, taking advantage of growing expertise in wake control and overall site optimization, according to the Berkeley Lab's recently-published Wind Technologies Market Report, commissioned by the Department of Energy (DOE).

Nearly a quarter of larger wind power projects built in 2016 and 2017 used turbines with multiple hub heights, rotor diameters or capacities, the report said.

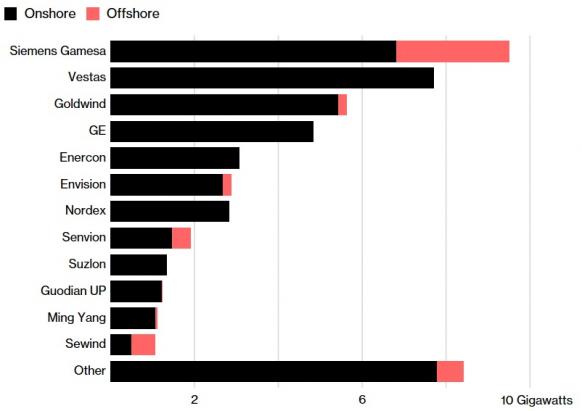

Top turbine manufacturers' share in 2017 (global)

(Click image to enlarge)

Source: Bloomberg New Energy Finance (BNEF).

Operations and maintenance

Rising turbine capacities and increasing wholesale market exposure have placed increasing importance on minimizing downtimes.

GE has introduced more robust manufacturing processes and adapted the design to improve operational performance, it said.

Design features include a larger nacelle platform to facilitate up-tower repairs by service personnel. The hub, which is mounted on the main shaft, is entered through hatches located on the nacelle to ease service access.

The platform also incorporates the latest data analytics and predictive maintenance systems.

Together, these improvements will "improve reliability and lower lifecycle costs”, Wells said.

Global reach

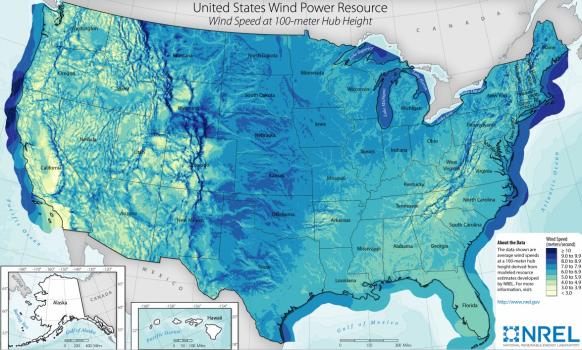

In recent years the U.S. Interior region has dominated U.S. wind power growth, but better site access for larger turbines could unleash growth in southern regions.

GE's new turbine design will be most effective in locations with lower wind speeds (class 3 or 4) and supportive wind industry infrastructure and market models, Baring-Gould said.

In the U.S., this would include many areas in the southeast and parts of the southwest.

US wind resources at 100 m hub height

Source: National Renewable Energy Laboratory (NREL)

GE’s new design and installation features could also boost development in central, eastern and southern Europe, Baring-Gould noted.

“Although it might not be this platform, the knowledge gained in using segmented blades and more modular drive train options may also help expand the markets in other less developed part of the globe where transportation logistics are challenging for 2-3 MW platforms”, he said.

Wells also predicts opportunities in Asia, Australia and the Americas.

“In reality, the platform has application around the world”, he said.

By Neil Ford