New CSP report offers learnings from Crescent Dunes flop

A new global CSP report will help developers understand key failings at Crescent Dunes and other early plants and improve investor confidence in future projects, the US National Renewable Energy Laboratory (NREL) told New Energy Update.

Related Articles

As a dispute over failures at the Crescent Dunes tower plant in Nevada rumbles through US law courts, new findings on global CSP performance could help boost investor confidence in the sector.

The US National Renewable Energy Laboratory (NREL) has studied 90 CSP projects, including Crescent Dunes, and will publish its findings in the coming weeks.

Developed by SolarReserve, the 110 MW Crescent Dunes plant was the first large-scale solar tower project with molten salt storage.

Last October, Nevada utility NV Energy terminated its offtake contract for Crescent Dunes after the plant failed to meet output expectations. Project company Tonopah Solar Energy then defaulted on repayments to a $737 million federal loan guarantee. Since then, SolarReserve has ceased operations and contested Tonopah board placements and project vehicle structures through law suits.

Since Crescent Dunes, the CSP industry has had to rebuild investor confidence in CSP tower and storage technology. Despite progress, CSP projects continue to incur higher cost of finance than PV and wind.

The owners of Crescent Dunes have offered little detail over its failings but NREL's comprehensive study indicates the industry can avoid similar failures going forward.

“The issue at the project can be avoided...it’s not endemic of all plants out there," Mark Mehos, NREL CSP Program Manager and researcher on the report, told New Energy Update.

To improve reliability, CSP designers and operators must fully understand the impact of sudden or short-lived operating conditions on all components, "including the thermal energy storage tanks,” Mehos said.

Tank troubles

Crescent Dunes was brought online in October 2015, a year behind schedule. In court filings, SolarReserve blamed Spanish EPC group ACS Cobra for construction delays and “grossly deficient work” during the construction period.

Output was below target during the first year of operations. A year after start-up, the plant was shut down for eight months due to a leak in the molten salt storage system. By 2018, the average capacity factor of Crescent Dunes was 20.3% compared with a planned factor of 51.9%, according to EIA data.

SolarReserve blamed ACS Cobra, designer of the salt storage tanks, for the leak, but does not appear to have filed legal action against the company. ACS Cobra declined to comment on the matter.

NREL's latest analysis shows that salt tank designs can be further improved, Mehos said.

New designs which have been studied include relocating hot and cold salt pumps to eliminate the need for long pump shafts and reduce downstream infrastructure costs, and alternative welding practices.

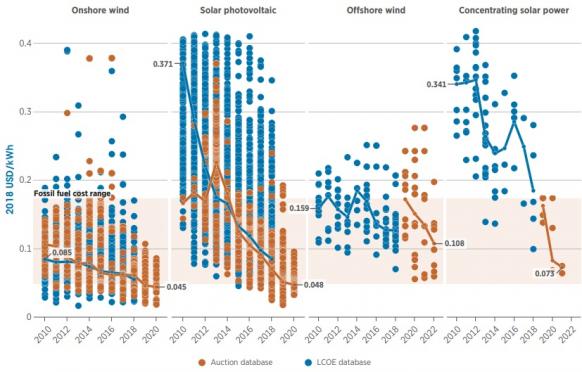

Global costs for solar, wind in 2010-2022

(Click image to enlarge)

Source: International Renewable Energy Agency report,'Renewable power generation costs in 2018' (May 2019).

The early deployment of new technology typically raises first-of-a-kind challenges and greater deployment levels will help reduce the risks, Mehos said.

Higher early deployment rates for CSP parabolic trough technology reduced the cost of finance compared with tower plants. The inclusion of parabolic trough on ACWA Power's 950 MW Noor Energy 1 CSP-PV plant in Dubai improved the risk profile for the project, Rajit Nanda, Chief Investment Officer at ACWA Power, noted in 2018.

“The tower plants have their issues and that is simply because the volumes haven’t been there," Mehos said.

Field learnings

Since Crescent Dunes, CSP tower developers have improved reliability, but concerns remain.

Brought online in December 2018, ACWA Power's 150 MW Noor III CSP tower with storage in Morocco is understood to be offline due to an undisclosed issue.

In the first few months of operation, the plant exceeded performance targets on output and storage integration. Spain's Sener is the main technology provider and EPC contractor for the project.

A key area of ongoing focus for Empresarios Agrupados (EA), contracted owner's engineer for Noor III, was the integration between the solar island and the rest of the plant, Xavier Lara, Senior Consultant at EA, told New Energy Update in May 2019.

Project partners would also closely monitor the ability of the steam turbine to withstand “thermal stresses associated with the temperature gradients during the frequent ramp-ups and cooling,” Lara noted.

More recently, China's Supcon Solar exceeded six-month output targets at its 50 MW Delingha CSP tower plant with storage in Qinghai province.

Built in just 18 months at an attitude of 3,017 m, the plant includes seven hours of molten salt storage. Supcon Solar aims to achieve an average fulfilment rate of over 100% for the first year, far higher than typical rates of 70 to 80% set out in global EPC contracts.

CSP developers will be hoping projects like Delingha can inject further confidence in tower and storage technology and reduce the cost of finance. Combined with lower capex costs, this would help attract new customers.

Reporting by Kerry Chamberlain

Editing by Robin Sayles